Industrial and manufacturing plants and processes are increasingly becoming intelligent. While digital transformation was driving change before the pandemic, the pandemic has accelerated this trend. Supply chain disruptions, local and regional lockdowns, and a growing understanding of the benefits of remote workforces have sparked an increased appreciation of the value of digital technologies.

For channel partners, it is an opportunity to address the potential of improved returns from the adoption of digital technologies within industrial businesses, referred to as the potential of Industry 4.0.

The digitalisation of industrial processes requires an intermediate software layer that manages the flow of data from industrial control systems into enterprise application systems. While the Industrial Internet of Things is a recent adoption cycle emerging from the digital side, manufacturing execution systems have been the legacy backbone for data management inside industrial control systems.

Increasingly the two sides are merging, and channel partners from both the industrial side and the digital side have an opportunity to bridge the gap, driving tremendous value for their customers.

Channel partners from the industrial side and the digital side have an opportunity to bridge the gap driving value for customers

Enterprises dependent on large-scale plant and industrial machinery now have the opportunity to better manage their large capital investments by adding agility to asset performance management and by building the digital twins of their plants. By bringing in digital tools like big data, analytics, artificial intelligence, machine learning, and cloud, industrial plants can be better managed in real-time.

Their past, current, and future performance metrics can be presented on easy-to-use dashboards carried around on executives’ mobile phones or tablets.

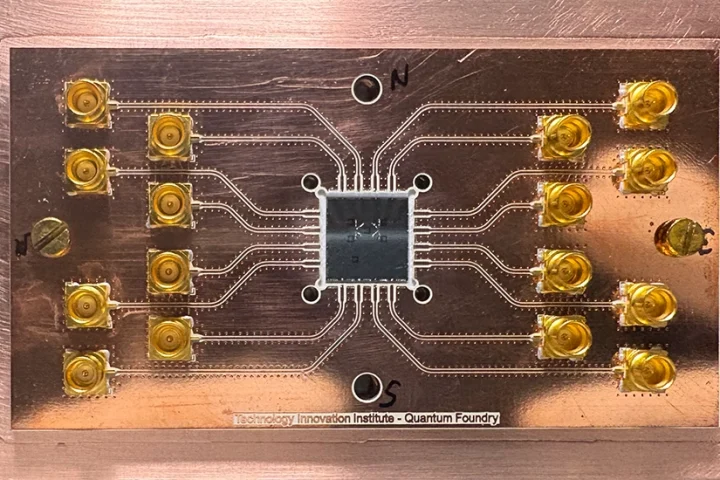

The digital twin is a virtual replica of the plant engineering infrastructure that is enabled by data. Using 3D modeling, advanced engineering, and visualisation tools, complex engineering and plant routines can be made visible and controllable on digital dashboards. Similarly, Asset Performance Management, a key industrial operating tool, has also been digitally transformed. Combining big data, cloud, artificial intelligence, digital twin, augmented reality, and other similar digital technologies, APM provides a real-time dashboard for proactive decision making.

Digitally managed, APM can reduce equipment failure, bring down overheads of maintenance costs, and reduce unpredictable downtime. This benefits the utilisation of assets, extends equipment life, and identifies underperforming assets.

Channel partners have an opportunity to map expectations of plant managers who have traditionally not had visibility to this detail

However, in the beginning, these platforms and solutions will not be interoperable. Channel partners have an opportunity to map the expectations of the plant managers, CIOs, CDOs, and CFOs who have traditionally not had visibility to this level of detail with in their operations.

Such proactive discussions by channel partners with their industrial customers can build better long-term engagement, deep and strategic relationships, benefitting the bottom line, and medium and long term cash flow of their customers.

Channel partners, therefore, need to skill themselves and build solutions for the following pain points of their customers:

- Enabling remote work: Engineering subject matter experts need to be enabled to work remotely and must have data visualisation tools to monitor plant operations virtually.

- Early warning systems: Predictive analytics as an integral part of the automated asset performance management strategy will be critical to avoiding unplanned downtime.

- Younger workforce: A new generation of digital-native workers will have a shorter attention span, shorter base line of experience, and expect a highly interactive user experience through inbuilt industry best practices using AI and ML.

- Production efficiency: As supply chain interruptions create havoc, digitally integrating demand planning with plant floor operations can help build agility.

Channel partners willing to embrace the challenge and opportunity of bridging the industrial and digital side of plant operations must be certified by their vendors. And that means training, training, and more training.

Finally, the gains for channel partners are as much about innovative solutions as about becoming a forward-looking, strategic advisor for their industrial enterprise customers.

As digital technologies transform many industrial platforms, channel partners need to be ready to play the role of innovative solution providers and strategic advisors for industrial customers, says Kerry Grimes, Head of Partners, AVEVA.