Eaton released updated versions of its Tofino industrial Ethernet security solution. Hardware variants now include fibre optic interfaces to handle long distance applications, improved configurator software further simplifies set-up, and new software module options enable deep packet inspection (DPI) firewall capabilities for additional industrial protocols. The 9202-ETS MTL security solution continues to provide the highest level of network security for process automation applications, maximising plant uptime and process availability while protecting it from cyber security threats.

Roger Highton, Product Line Manager, Eaton says “Traditional firewalls are not designed for control systems or industrial threats, thereby putting essential utilities at risk, and each year, damage to critical infrastructure from network incidents and cyber-attacks runs into billions of dollars. The MTL 9202-ETS gives process managers in the power, utilities, oil and gas, and water industries cost-effective security protection that is highly effective and easy to install.”

The latest version of the MTL Tofino security solution introduces three new hardware variants that add fibre optic interface capabilities. Until now, an additional media converter was required with the Tofino security appliance when integration into a fibre optic network is required. The new fibre versions provide a one box solution for long distance applications where fibre optic cable is used. The new range supports both multi-mode fibre and single mode fibre which is widely used in process applications for long distance applications. Additionally, both one and two fibre port versions are available.

Updated configurator software ensures the MTL Tofino security appliance is even simpler to install and set up, with v3.2 adding asset detection and discovery, plus assisted firewall rule generation, based on network traffic flowing through the device.

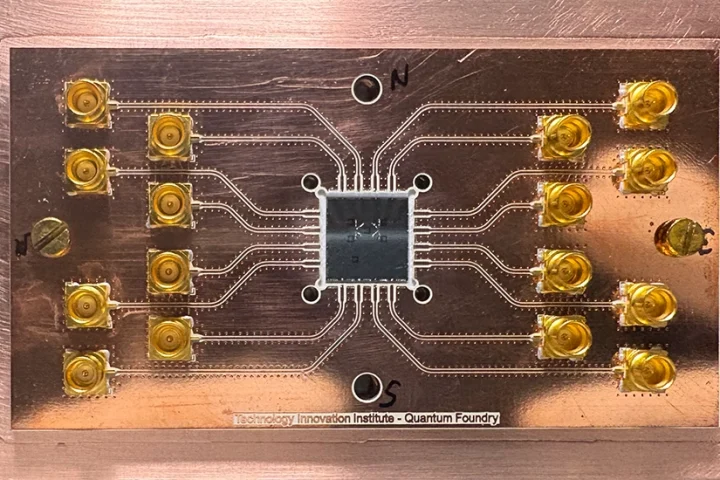

The 9202-ETS MTL security appliance is a layer 2 Ethernet bridge with no IP address, making it almost impossible to detect or attack. Its rugged industrial form factor is suitable for use in harsh and hazardous environments, with a robust metal housing for DIN rail mounting, and -40°C to +70°C operating temperature ratings together with Class 1 Division 2 and ATEX Zone 2 hazardous area approvals. This ensures it will give years of reliable service, providing secure networks with security zones as per NERC, ANSI/ISA and IEC standards. It protects industrial networks from cyber-security vulnerabilities, delivering defence in depth for a wide range of DCS, PLC, SCADA, networking and automation systems.