Successful food manufacturers of the future will be the agile innovators who prioritise connections with consumers becoming increasingly overloaded with information on brands and products. That is the view of Karen Stanton, Director, Global Marketing and Branding of International Flavors and Fragrances, an innovator of scent, taste and nutrition. Speaking ahead of the Gulfood Manufacturing FoodTech Summit, which runs at the Dubai World Trade Centre, Stanton said that as the food and beverage landscape evolves at a rapid pace, manufacturers must listen to what consumers are seeking – now more than ever.

“Understanding, listening and participating in consumer understanding is crucial to keeping abreast of the rapidly changing food and beverage landscape. It is not enough to do a couple of focus groups or product tests to understand the nuances of these shifts – we need to have knowledge of the drivers behind the change and shifts in lifestyle – all of these help us to predict the future direction,” said Stanton who will address the Summit on the Future of Taste, examining seismic consumer trust shifts, resource constraints and case studies of emerging trends with her transformational forecast.

“Consumers are in a new information battlefield, navigating an increasingly chaotic and complex matrix of information, influence and trust. Traditional sources of information will deteriorate and to establish credibility, brands will need to prioritise trust and transparency in this new world.”

Stanton added that corporations need to rethink their way of operating and become more agile innovators or risk losing out: “Innovation needs to become more agile, more fluid – the days of waiting years for new technology are over. We need to be structured to support the faster discovery and implementation of technology and design to deliver what consumers are looking for – great health and nutrition and great taste. Companies are at a crossroads! We will need to re-engineer business models to react to fast-scaling competition and on-demand expectations. Successful organisations of the future will adopt new approaches as the world changes.”

Stanton is among experts from 10 nations who will take to the Summit platform to explore the realities of the Factory of the Future, which will echo around Gulfood Manufacturing, the region’s biggest food and beverage processing industry event. German technology powerhouse Siemens has signed on for the show to push its digital transformation solutions which it says can answer demand for speedier innovation.

“Rapidly changing consumer expectations are placing companies under increasing pressure to turn around ever more customised products within the shortest possible time, and all to an optimum, consistent standard of quality. The key to successfully addressing this challenge is digitalisation; it allows companies to simulate, test and optimise products, production processes and plants in a virtual environment on the basis of a digital twin, explained Siemens’ Athar Siddiqui.

Siemens will demonstrate how manufacturers can use the digital twin of a product, machine or a whole plant to generate added value. “When creating a recipe for a new product, for instance, data relating to the ingredients is transferred directly to the label, taking into account legal regulations. This is made possible by the Teamcenter shared data platform. Using the plant’s digital twin, it is also possible to test planned changes and the effects these may have on production. This capability permits industries to significantly increase innovation speed and boost productivity, and also to take the lead in defining whole new business models,” added Siddiqui.

US ingredients provider Ingredion is bringing its Tour of Tasty Trends, to the Gulfood Manufacturing 2018 with culinologists presenting the latest trends incorporating new ingredients as well as clean-label solutions. The Tour, says Esen Kural, Regional Sales Manager, Ingredion Middle East, will be a manufacturers’ survival guide to the transformational era.

“It will show food and drink manufacturers how they can overcome processing challenges and meet consumer and industry demands, while retaining the deliciousness of their products. Ingredion’s on-stand concepts will tackle challenges including specific health and nutritional requirements, affordability and attaining the perfect consumer-winning texture,” he said.

Ingredion has already invested in the region with Dubai being home to one of its Idea Labs – a network of global innovation centres – which, says Kural, has given it unique regional industry insights and opportunity alerts.

“Many trends underpin the burgeoning food and drink industry across the Middle East. In the dairy industry, we continue to see the dominance of indulgence but with a strong focus on texture. Here, if dairy goods can’t maintain their stability and eating consistency in extreme weather conditions, such as intense heat, then it isn’t worth the indulgence of purchasing,” he added.

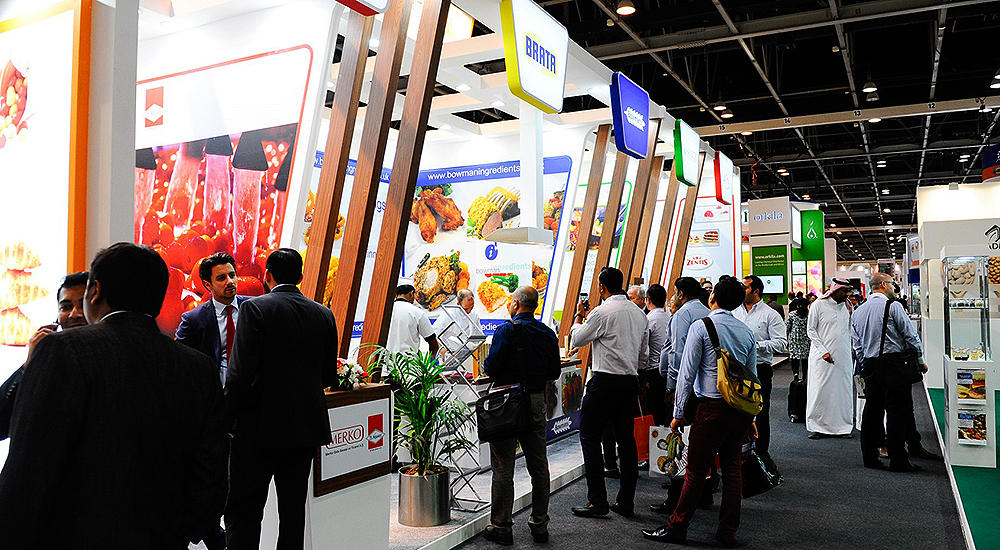

Innovation is a key focus of Gulfood Manufacturing, which brings together over 35,000 visitors and 1,600 suppliers from 60 countries showcasing the latest F and B manufacturing business improvement tools. The show will feature Innovation Demos to ensure that visitors, including some of the 2,000 C-level executives being hosted on its Big Buyers programme, get deep insights into the technology on offer. The tours will take in the show’s five dedicated sectors – Ingredients, Processing, Packaging, Automation and Controls, and Supply Chain Solutions.

Key takeaways

Understanding, listening and participating in consumer understanding is crucial to keeping abreast of the rapidly changing food and beverage landscape.

Innovation is a key focus of Gulfood Manufacturing, which brings together over 35,000 visitors and 1,600 suppliers from 60 countries showcasing the latest F and B manufacturing business improvement tools.