SunMoney Solar Group, which runs the largest community solar program in the world and has its own asset-backed clean energy token, the SDBN2, recently invested in a revolutionary tyre-recycling technology. The futuristic technology’s efficient system, whose solution SunMoney Solar invested in, has a zero carbon footprint of its own, along with a minimal energy requirement during the recycling process, thus drastically reducing its environmental impact. The tyre recycling technology is part of SunMoney Solar’s larger effort to create a more sustainable future for all of its stakeholders. As part of its commitment to sustainability and corporate responsibility, SunMoney Solar is working hard to develop cleaner energy sources and investments.

The all-new tyre recycling technology has been developed by a cooperation between an Austrian and a Swiss company and uses advanced machinery and processes to break down used tyres into their component materials without releasing any harmful emissions into the atmosphere i.e. zero carbon footprint. The material produced can then be reused to create new products such as insulation foam, playground surfaces, rubber mats or even artificial turf for sports fields.

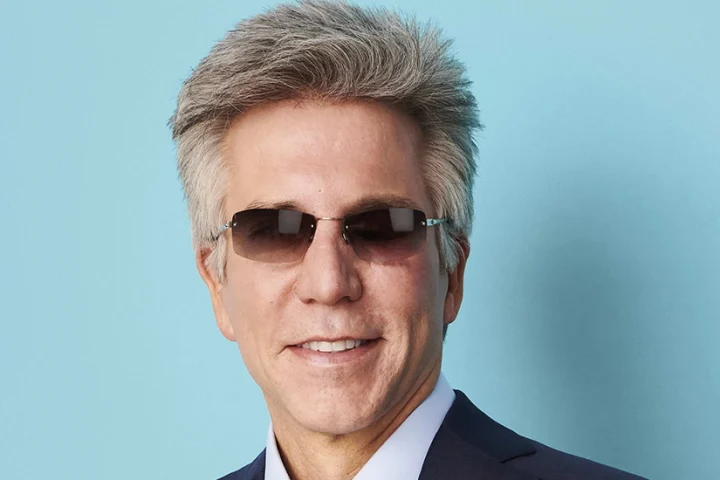

“This unique technology is an incredible innovation that will help us reach our sustainability goals faster,” said Zoltan Rendes, Chief Marketing Officer, and Chairman of the Board at SunMoney Solar Group. “We are thrilled to partner with them and look forward to seeing their technology become a staple in the industry. This is an incredible advancement in green technology. By eliminating emissions from the process, we can significantly reduce our carbon footprint while still producing high quality recycled products,” he added.

Tires, when burnt as a source of fuel instead of recycling them properly, emit a lot of harmful chemicals in the environment. They also throw off tiny plastic polymers into their surroundings that more often than not end up as pollutants in waterways. The groundbreaking technology is set to have a major impact on global waste management practices. By utilizing this advanced recycling process, companies can reduce their environmental footprint while still producing high quality products without any additional cost or effort. Not only does this process help reduce waste by diverting it from landfill sites; it also helps save money on purchasing new materials for manufacturing purposes. SunMoney Solar’s investment in this technology marks another milestone on its mission to create more sustainable products and services for consumers around the world. With this new partnership, SunMoney Solar Group hopes to bring about meaningful change within the industry through increased access to innovative technologies that are both eco-friendly and cost effective. The company also sees great potential for this technology in blockchain, and in foraying into asset-backed cryptocurrency tokens for tyre recycling technology, after the success of its previous Solar backed asset token, SDBN1 and SDBN2.

In addition to its environmental benefits, this state-of-the-art tyre recycling technology also has economic advantages. By streamlining the process of sorting and recycling materials, it reduces labour costs and increases efficiency throughout the entire supply chain. This makes it attractive for businesses looking to cut costs while still producing high quality recycled rubber and steel products. With its investment in this innovative solution, SunMoney Solar is taking a major step forward towards being more effective in the tyre recycling space and creating a greener future through sustainable solutions that are both economically viable and environmentally responsible. This sustainable new system promises to revolutionize the tyre recycling industry by providing an efficient and cost-effective method for processing tyres with zero emissions involved.