Tenable, announced an integrated Cyber Exposure solution to provide a unified view of cyber risk spanning information technology networks and operational technology, from enterprise applications to industrial control systems. Security leaders can rely on a single platform to measure, manage and reduce cyber risk across both IT and OT environments with Tenable Industrial Security now integrated with Tenable.sc formerly SecurityCenter for vulnerability management on-premises.

Digital transformation means that the days of fully air-gapped OT assets are largely gone. Modern OT environments increasingly interconnect with IT, resulting in a complex, sensitive and vastly expanded attack surface. As effective risk management is built on a unified understanding of the entire IT OT attack surface, organisations are shifting responsibility for OT security to the Chief Information Security Officer.

Yet traditional IT security solutions lack the ability to continuously discover and assess sensitive OT assets. Conversely, most OT security solutions do not translate to the world of IT. This lack of holistic visibility creates security blind spots and increases the chances of mission- and safety-critical systems being compromised or taken offline. An attack on a high-value OT asset, for example, may begin by compromising a traditional IT asset and then moving laterally.

When used with industrial security, Tenable.sc solves this problem by delivering clarity into an organisation’s converged IT OT environments. Tenable.sc leverages industry-leading Nessus scanners to gather a wealth of security-related information from IT-based assets on OT and IT networks. Tenable.sc then combines that information with passively collected asset and vulnerability data from Industrial Security, which provides safe, reliable asset discovery and vulnerability management purpose-built for OT environments.

Designed for critical systems that require a non-intrusive approach to vulnerability management, Industrial Security is an OT-native solution that helps identify and prioritise OT risks so organisations can keep safety-critical production assets secure and fully functional. The integration of Tenable.sc and Industrial Security provides the first complete picture of IT and OT assets together, identifying exposures and vulnerabilities across the entire enterprise and helping organisations prioritise and manage cybersecurity against business risk.

Integrated solutions accelerate the time-to-detect and remediate issues through a greater breadth of visibility across the modern attack surface, depth of analytics, and integrated data and workflows, fostering better collaboration across Security and IT Operations teams. Expanded OT Asset Coverage, includes coverage of several thousand new devices from leading industrial manufacturers, such as Yokogawa and Emerson.

These new manufacturers join the top ten leading industrial manufacturers, including Siemens, Schneider, Rockwell Allen-Bradley, Honeywell, Mitsubishi and others, whose devices are already covered by Industrial Security.

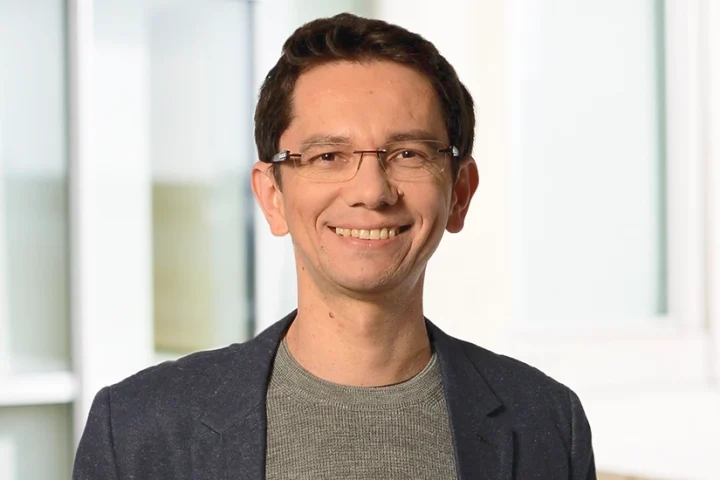

“The interconnectedness of digital infrastructure today means the security of IT directly impacts OT, and vice versa. Without a single, unified view into converged IT OT environments, CISOs are basically being asked to defend their organisations blindfolded and with one arm tied behind their backs. It is bad cyber strategy and it places the business at serious risk,” said Renaud Deraison, Co-founder and Chief Technology Officer.

“Tenable.sc is a platform used and loved by thousands of CISOs and security teams for on-premises vulnerability management and the integration with Industrial Security for comprehensive IT OT visibility is a natural and obvious extension of our leading vulnerability management capabilities.”