Artificial intelligence’s value in the industrial space is undeniable. It has the potential to skyrocket rates of profitability in manufacturing by an average of 39% by 2035. This is because artificial intelligence brings a fundamentally different approach to decision making that ultimately will produce better results.

It uses data to learn patterns that may not be obvious to the human eye faced with hundreds of parameters and inputs versus just a handful of data points in the pre-digital days.

Artificial intelligence has potential to skyrocket rates of profitability in manufacturing by an average of 39% by 2035

General artificial intelligence and machine learning models are not enough. Instead, models must be applied specially to realistic applications, including energy management, asset performance, and operational productivity, to make artificial intelligence worth the financial and human resource investment — not to mention the time.

Bear in mind that artificial intelligence technology is just the foundation. Actionable insights gleaned from continually training and re-training models hold the real key to the data-driven decision-making behind valuable business outcomes.

Artificial intelligence uses data to learn patterns that may not be obvious to the human eye faced

Using artificial intelligence can answer business-critical questions on a daily, even hourly, basis, but companies must leap over three current roadblocks:

- Data preparation and operationalisation

- Artificial intelligence lifecycle management

- Making artificial intelligence meaningful across organisations

In the industrial space, that question often is, how can companies constantly improve efficiency while ensuring uptime? Artificial intelligence can answer this question with data-based models made to predict outcomes such as when will this asset fail? Or where and when is energy being wasted?

But therein lies the challenge. Critical operations and industries demand accuracy, so investing in experimentation is crucial for building the right models, which always will be as dynamic as the human intelligence they are designed to emulate.

Models must be applied to energy management, asset performance, operational productivity, to make it worth the financial and human resource investment

Artificial intelligence engineers do not always know what any given artificial intelligence model’s outcome will be, as outcomes depend on how predictive the data are. Artificial intelligence models therefore must start with a certain level of accuracy and improve over time and, in turn, be re-trained, re-versioned, and re-deployed within situational context and end user feedback.

On the other hand, innovative artificial intelligence technologies now make it possible to manage industrial operations and maintenance from almost any remote location.

AI models must start with a level of accuracy and in turn, be re-trained, re-versioned, and re-deployed within situational context

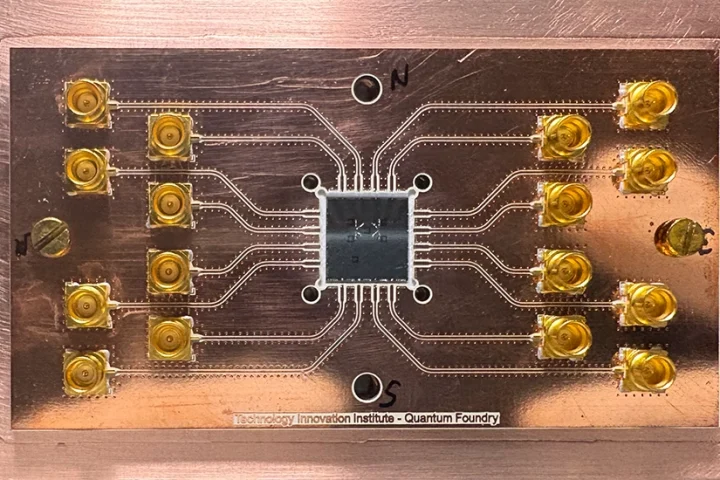

With the implementation of the industrial internet of things digital twins, cloud computing, and artificial intelligence, industrial operations are overcoming supply chain, production, and distribution complexity obstacles by linking core industrial processes into a centralised digital environment.

Schneider Electric is invested in developing predictive analytics and condition management tools to enable customers to predict machine failure long before downtime actually occurs. For example, Schneider Electric’s Realift Rod Pump Control leverages Microsoft machine learning capabilities to monitor and configure pump settings and operations remotely.

Actionable insights gleaned from training and re-training models hold the real key to data-driven decision-making

It sends personnel onsite only when necessary for repair or maintenance when Realift indicates an issue. Realift is designed to operate in harsh environments and remote locations and is geared to optimise energy efficiency through improved performance for the region’s oil and gas industry.

The company has also announced the impact of a new multi-million dollar investment in machine learning tools and data science. This investment brings artificial intelligence-assisted advising to its energy and sustainability services offering, thus providing its clients access to next-generation digital tools.

Engineers do not always know what any given artificial intelligence model’s outcome will be Outcomes depend on how predictive is the data

This improves the insights and analysis of a company’s energy and sustainability portfolio, driving more efficient value and bottom-line impact in pursuit of climate change resilience and other resource-saving related targets.

AI can answer business-critical questions on a daily and hourly basis but enterprises must leap over roadblocks like data preparation, lifecycle management.